Instant Quoting

Rapid Prototyping

High-Volume Production

injection-molding-inqList.title-0

injection-molding-inqList.content-0

injection-molding-inqList.list-0-name0

injection-molding-inqList.list-0-name1

injection-molding-inqList.list-0-name2

Get an instant quote today.

Trusted by Engineers and Purchasing Leaders at the World’s Most Successful Companies

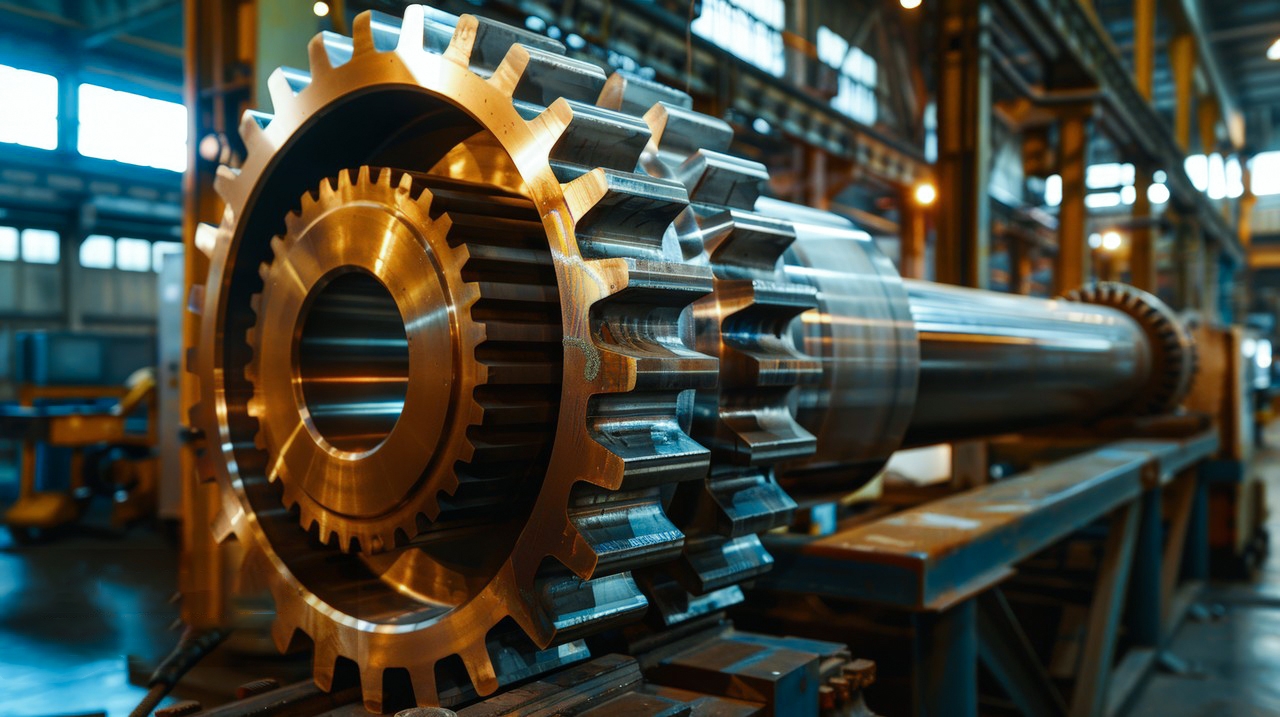

injection-molding-introduction.title

injection-molding-introduction.dsc

Service

Product Showcase

injection-molding-productShowcase.dsc

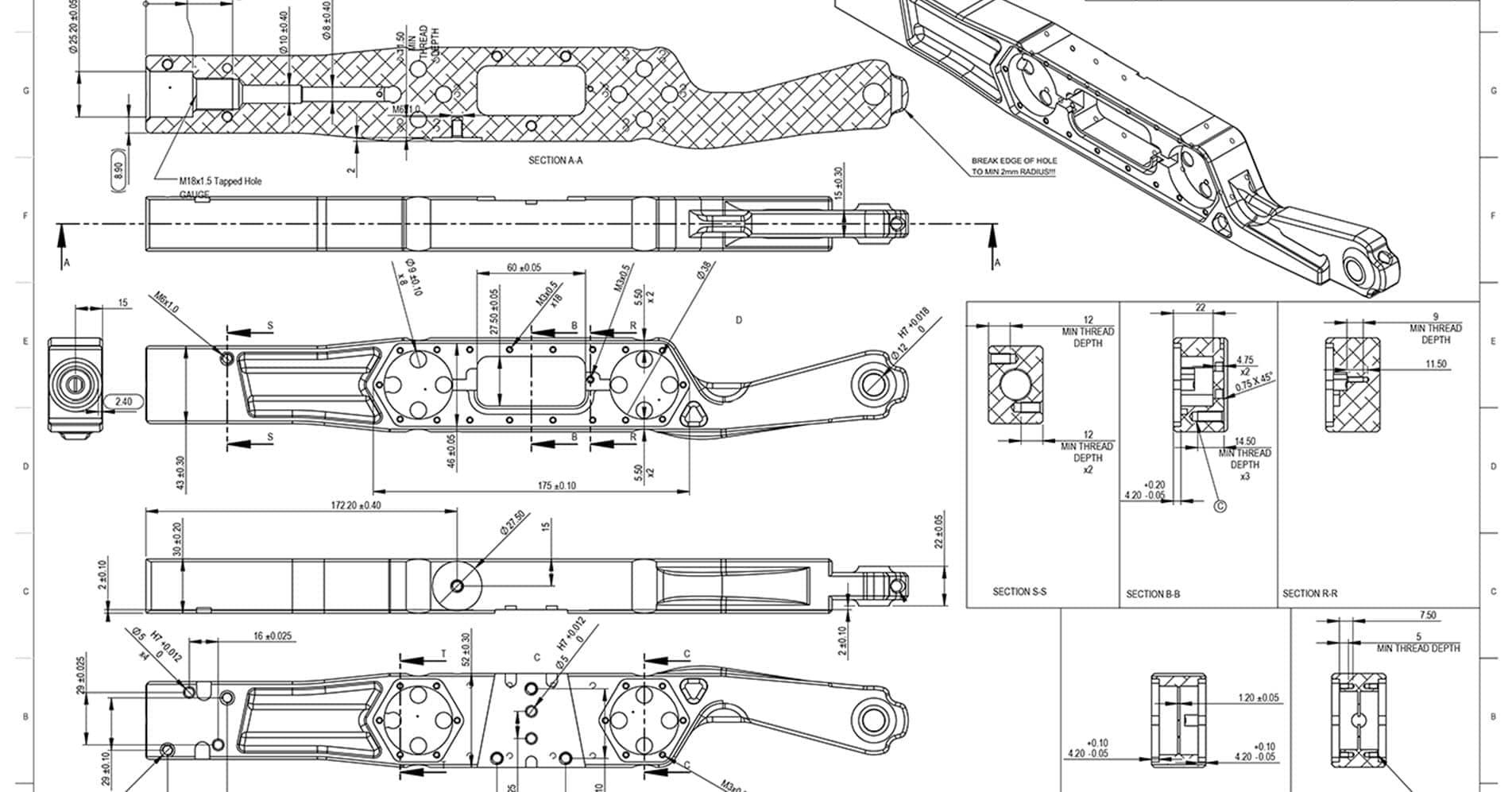

Tolerances

injection-molding-tolerances.dsc

Feature

Description

injection-molding-tolerances.feature-0

injection-molding-tolerances.dsc-0

injection-molding-tolerances.feature-1

injection-molding-tolerances.dsc-1

injection-molding-tolerances.feature-2

injection-molding-tolerances.dsc-2

injection-molding-tolerances.feature-3

injection-molding-tolerances.dsc-3

injection-molding-tolerances.feature-4

injection-molding-tolerances.dsc-4

injection-molding-tolerances.feature-5

injection-molding-tolerances.dsc-5

injection-molding-tolerances.feature-6

injection-molding-tolerances.dsc-6

injection-molding-tolerances.feature-7

injection-molding-tolerances.dsc-7

injection-molding-tolerances.feature-8

injection-molding-tolerances.dsc-8

injection-molding-tolerances.feature-9

injection-molding-tolerances.dsc-9

injection-molding-tolerances.feature-10

injection-molding-tolerances.dsc-10

injection-molding-tolerances.feature-11

injection-molding-tolerances.dsc-11

injection-molding-tolerances.feature-12

injection-molding-tolerances.dsc-12

injection-molding-tolerances.feature-13

injection-molding-tolerances.dsc-13

injection-molding-tolerances.feature-14

injection-molding-tolerances.dsc-14

injection-molding-tolerances.feature-15

injection-molding-tolerances.dsc-15

injection-molding-tolerances.feature-16

injection-molding-tolerances.dsc-16

injection-molding-tolerances.feature-17

injection-molding-tolerances.dsc-17

injection-molding-tolerances.feature-18

injection-molding-tolerances.dsc-18

Material Selection

injection-molding-materialSelection.dsc

Metals

- Titanium

- Steel

- Stainless Steel

- Zinc Alloy

- Chromium-Nickel Alloy

- Brass

- Copper

- Aluminum

- Bronze

- Cold Rolled Steel

- Nickel

- Silver-Tin Oxide

- Cast Iron

Titanium is known for high strength, low weight, and corrosion resistance. We process grades like Ti-6Al-4V, Ti-5Al-2.5Sn, Ti-6Al-4V ELI, and Ti-Grade 2, which are widely used in aerospace, medical implants, and sports equipment.

Plastics

- Polycarbonate (PC)

- Polyoxymethylene (POM)

- Polyphthalamide (PPA)

- Polyphenylene Sulfide (PPS)

- Teflon (PTFE)

- Polyvinyl Chloride (PVC)

- Ultra High Molecular Weight Polyethylene (UPE)

- Polyether Ether Ketone (PEEK)

- Nylon (PA)

- Glass-Filled Nylon

Polycarbonate is a transparent, highly durable plastic known for its superior impact resistance. We offer different grades suitable for eyewear lenses, medical devices, and protective equipment.

We offer customization based on your specific material requirements, if you need a material not listed here, our team can source and process ito meet your exact needs

Surface Finishing

injection-molding-surfaceFinishing.dsc

Advantages & Features

injection-molding-advantagesFeatures.dsc

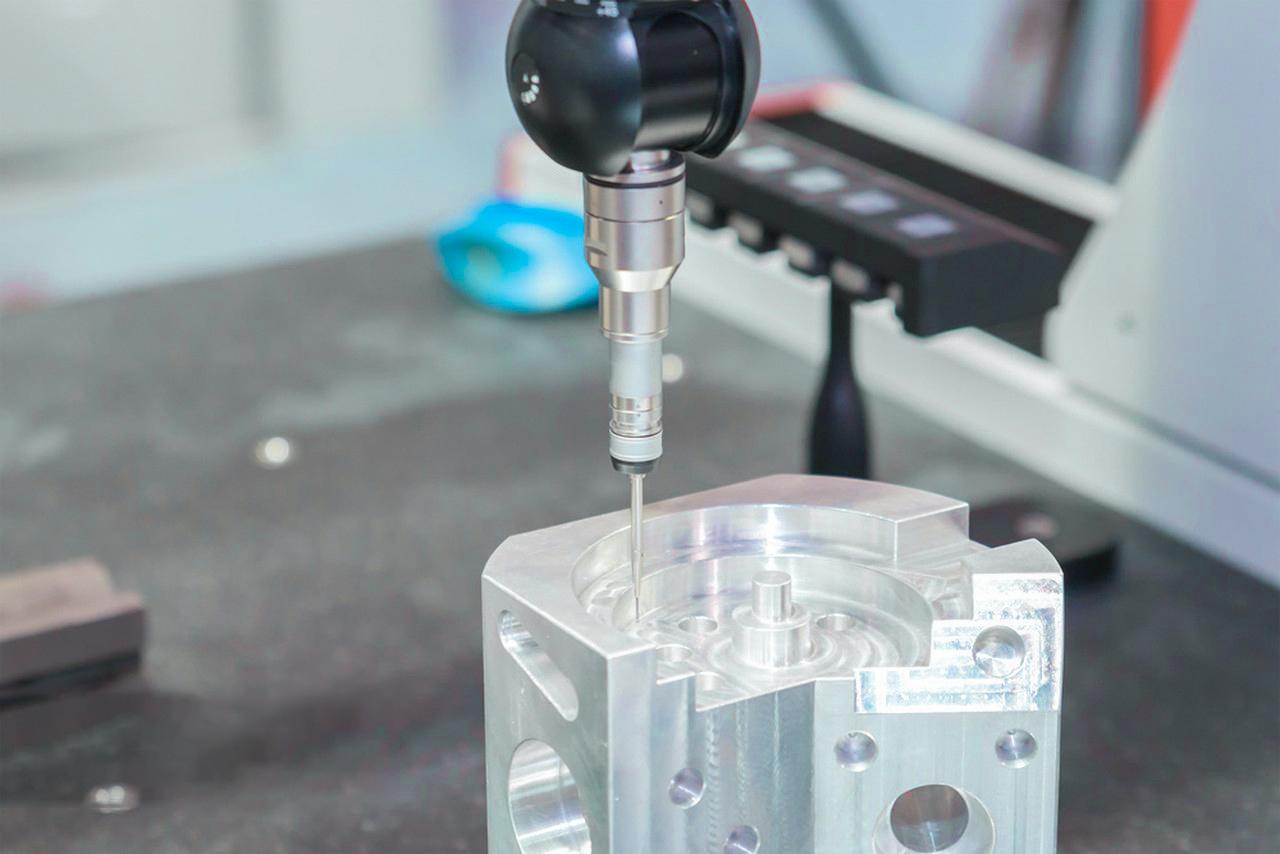

Quality Control

injection-molding-qualityControl.dsc

In-Process Inspections

Before any part leaves our facility, it undergoes a thorough final inspection. We use advanced measurement tools to verify that every component meets required specifications and precision standards, ensuring the highest level of quality before delivery.

Final Inspections

Before any part leaves our facility, it undergoes a thorough final inspection to verify its quality and precision. We use advanced measurement tools and techniques to ensure that each part meets the required specifications and standards.

Precision Measurement Tools

injection-molding-qualityControl.tool

Certified Quality Standards (ISO 9001, ISO 14001, IATF 16949, AS9100D)

Our commitment to quality is backed by ISO 9001 certification, which ensures our quality management system is consistently effective and continually improving. We also adhere to ISO 14001, IATF 16949, and AS9100D standards, ensuring we meet the needs of various industries while maintaining environmental sustainability and operational excellence.

Continuous Improvement

We believe in continuous improvement and regularly review our processes and practices to identify areas for enhancement. By investing in the latest technologies and training for our staff, we strive to maintain our reputation for quality and innovation.

Latest News

Stay updated with the latest news and announcements from LS Manufacturing. Explore our latest articles below.